In the current fenestration world and following current architectonic tendencies, glazing area sizes are constantly increasing and frequently windows are reaching 120 kgs. in weight as well as seeing requests for configurations up to 150 kgs.

These configurations mainly due to three reasons:

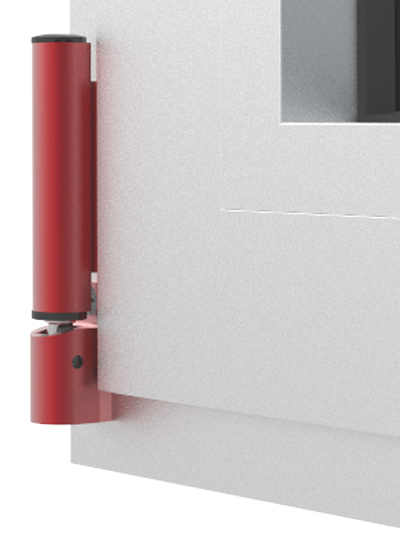

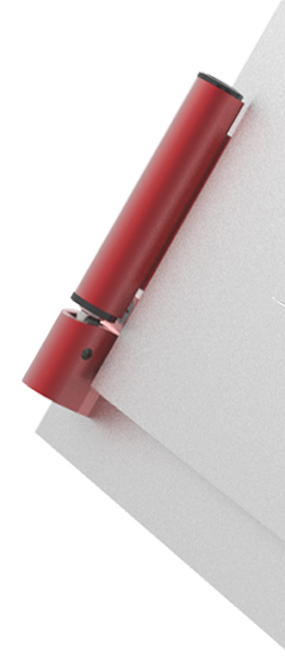

Because of these reasons, STAC has decided to launch a new tilt-turn configuration that includes new hinges and friction stays that are especially designed for heavy loads, that are characterised by their strength, assembly and adjustments and therefore a hardware that conforms with current expectations.

Thought to be trust

One of the main design premises was to provide extra security systems for the hardware in order to keep working despite of poor installation conditions or other kind of failures.

One of the most frequent types of mistake made during installation of classical tilt-turn hinges is the height adjustment and it is worse if the window is much heavier. This adjustment tends to be in the lower area of the sash and means the sash hinge blade has to be loosened so that the window can slide upwards with a degree of freedom.

The fact that in order to loosen these screws with a load is a problem in itself due to many windows are physically limited to a 90° opening or less (e.g. due to columns, walls etc.) and access to the screws is very complicated. Also a height adjustment has to be made, and for example in the case of a balcony or a Pladur type window, it is very complicated because the allen key does not fit in the lower part of the window. Finally, the screws that were loosened have to tightened again and not only was it difficult to loosen them but even worse to tighten them with all of the load on the sash.

Ultimately, the probability that something has been badly tightened or not at all is high. The solution is to eliminate the probability of error by eliminating the problem so that all the adjustments are accesible from the outside and can be applied directly.

The effectiveness of simplicity

As explained previously, with highly loaded windows it is essential that the adjustments are simple, effective and direct but above all that they are reliable.

Therefore the same type of adjustment has been implemented in these hinges as the Anodic hinges and their effectiveness has been verified in numerous tests:

The most important in its rightful place

One of the factors that has been centred on in its design ,was to look for an added security system that avoids unnecessary scares, taking in to consideration that 160 kgs. is a weight that should be treated with respect. Taking in to consideration that the materials have a limited resistance, the profiles available are diverse and each extruder can vary the profile thickness even though they maintain the exact channel dimensions. Therefore the reliability of the hinges has to be ensured against a small possibility of the sash failing.

Therefore, two extra specific security measures have been implemented: