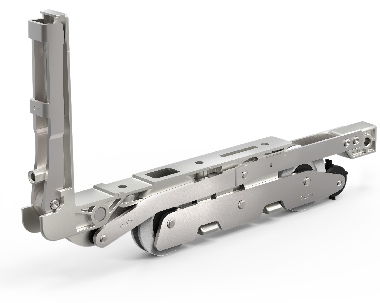

The first totally vertical elevating lift & slide. Our engineers have found the way to integrate within the carriage structure a system of rods and cams that make up a “pulley” type mechanism whereby the lift movement is totally vertical and the strength needed for lifting the same load is less. • Completely Vertical lifting. The sashes do not “sway” and nor do they pitch whilst moving downwards or upwards. • Less strength needed for lifting compared to traditional hardware with the same load. • A more compact unit that allows the wheels to situate themselves in the furthest possible extremes of the sash .• The transmission medium between carriages is independent of the wheel train. The workings of the wheel do not depend on the connection between carriages or how they are assembled. • The design guarantees an equal sash weight distribution over each wheel during all of the lifting kinematics and by design, each wheel supports exactly the same load value as its pair in a balanced way. This is fundamental in order to guarantee against wear during the life of the hardware, the correct working of the bearings without seizing, breakages, appearance of noise etc. Also it enables a correct dimensioning of the bearing features exactly. |

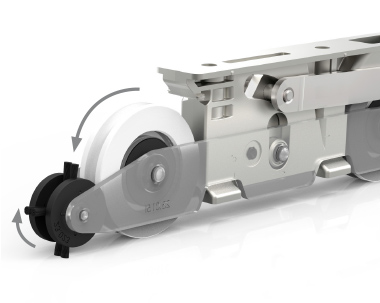

Dynamic track cleaning device.

The prescence of dirt in the guide rail is a factor that substantially affects the wear resistance and the useful life of the internal bearings in the wheels.In the Stac lift mechanism, a dynamic cleaning method is included which works by moving the sash along the guide rail and the tread on one of the wheels on the guide rail acts as a friction activated drive wheel which pulls it and causes it to turn on its axis at a greater speed due to the relation of radii between them. This drive wheel consists of one or two wheels made from elastomer material that turn together with a central nucleus made up of groups of tufts of fibre that are distributed around its perimeter so that not only does it sweep the guide rail but also the wheel channel and eliminates the dirt by expelling it outwards.

ADVANTAGES OF THE STAC LIFTING MECHANISM PRODUCTS.

• Three cremone face plate sizes in order to cover all sash height requirements.

• Extenders with or without a locking point for the cremone face plate.

• Stainless Steel 304 locking points with or without Microventilation.

• Extra carriages for loads between 300 & 400 kgs. that have the same characteristics as those already described.

• Frame locking points for multiple sash solutions.

• Fixed carriage for fixed sashes.